Two weeks ago, I had the chance to go to the inaugural O’Reilly Solid conference. Solid was billed as the Software / Hardware / Everywhere conference. The “Internet of Things” is a big buzzword right now, and I am glad that O’Reilly decided not to do an “Internet of Things” conference. There were plenty of “Internet of Things” exhibits and talks, to be sure, but the theme of the conference was bigger than that, and I think rightly so.

There is a lot going on in the hardware space, and Renee DiResta from O’Reilly Alphatech Ventures gave a good talk on hardware trends. The 2014 version of Mary Meeker’s Internet Trends report just came out, and I wonder if DiResta’s hardware trends will someday rise to similar stature. One of my favorite quotes from her talk: “software is eating the world, hardware gives it teeth”.

Changing the dynamics of working with hardware

The most important thing that is happening in hardware is that there is a lot of energy going into making it easy to design and fabricate physical things. This is true for electronic hardware but also for any product that has a physical embodiment.

Nadya Peek from the MIT Center for Bits and Atoms gave a talk on machine tools that can build machine tools. This is important because building and setting up machine tools is one of the critical path tasks in manufacturing physical objects. These tools could help cut the cycle time and cost for tooling. Also, in the spirit of the era, the designs for her machines are open source at http://mtm.cba.mit.edu/

Carl Bass, the CEO of Autodesk talked about how Autodesk took a step back and reimagined Autocad in the the modern world, against three principles:

- “Infinite computing” – treat computing power as if it were super cheap

- “Cloud based” – for collaboration and for delivery – you can get Autodesk Fusion 360 for $25/mo

- “Computational design” – put computing power to work to do parallel search / exploration of designs

The bottom line here is that anyone with $25/mo can have access to start of the art 3d CAD/CAM tools, based on the AutoCAD platform used by designers and engineers everywhere.

Microsoft did a live coding demo where they using an Intel Quark board to build a sound pressure meter. This was coupled with some very nice integration with Visual Studio. I’m not a big Microsoft/Intel fan for this space, but I think that this showed the potential for improving the toolchain and round trip experience for platforms like Arduino.

Julie bought our 11 year old a set of Littlebits as a way to get her some knowledge about electronics. She is a very hands on kind of learner and Littlebits seemed like a good vehicle for her. I didn’t do much homework on this because Julie did most of the research. So my impression of Littlebits was that it was sort of aimed at a kids education kind of space. Some of their marketing like “Lego for the iPad generation”, also gives that impression. Ayah Bdeir, the CEO of gave a great talk on LIttlebits and the vision of where it is going. The notion of making electronics very accessible, to the point where it can be viewed as just another material in someone’s creative toolbox, really resonated with the theme of Solid, and with our own angle on Littlebits. Littlebits is a great modular hardware platform that makes it easy to prototype electronics very rapidly, and it’s the first step in a longer journey of “materializing” electronics. It was a plus to be able to stop by the Littlebits booth and thank Ayah for Littlebits and the fact that I had to explain PWM to my 11 year old.

Vision

There were several talks which stood out because they painted a good picture of some things which are further out, but which appear to be obtainable given consistent application of product improvement and sufficient resources.

Neil Gershenfeld, the director of the MIT Center for Bits and Atoms, talked about fabrication as digital process. The key idea is that at the moment all the knowledge about fabrication is in the machinery doing the fabrication, not in the material being fabricated. He talked about what becomes possible when physical fabrication become more akin to programming.

Hiroshi Ishii from the MIT Tangible Media group talked about Tangible Bits (user interfaces based on direct manipulation of physical embodiments of bits) and Radical Atoms (materials that can change form based on digital information)

Ivan Poupyrev is now at Google but was a part of the Disney Research labs. He demonstrated several inventions from his time at Disney. Touche, which can turn lots of ordinary surface into touch sensitive input devices. He demonstrated a way to generate minute amounts of power locally without batteries, via rubbing pieces of paper together (as in turning the pages of a book). His final demo, Aireal, is a way of using puffs of air to create invisible haptic displays. The overall theme for all of these inventions was “How can we make the whole world interactive”?

Beth Comstock is the Chief Marketing Officer at GE. She talked about the fact that GE makes a huge range of machines of all kinds, and has experience with all kinds of materials and electronics. GE is looking ahead to taking those machines and enhancing them and the data that they produce via software. GE is a physical first company that is in the process of becoming digital, and leading us into a Brilliant Age. In this age:

- We’re going to have to learn to speak industrial machine – we need to be able to deal with the immense amount of data generated by sophisticated machines

- The Selfish Machine – machines will use data to introspect about their own performance and operation and alter their behavior, ask humans for help, or provide input for the design of the next generation

- The Selfless Machine – machines will be able to exchange data with each other to coordinate with other machines

- Machine Knock Down that Wall – machines will impact the process of making machines – rapid iteration of hardware design, open innovation processes

Robotics

In some ways, robotics is one of the culiminations of the software / hardware / everywhere mantra. There were lots of talks and exhibits on robotics at Solid. Here are 2 that stood out.

Rod Brooks is the founder of Rethink Robotics and a long time professor of robotics at MIT. I did some robotics as a grad student. Rod’s talk was a great way to get a small glimpse at the current state of the art. His company is doing some really interesting work in making industrial robots more flexible and easier to work with. One of the interesting points in his talk was that they are now working on ways to build robotic arms out of cheaper materials/hardware by leveraging more sophisticated software to compensate for the flaws of cheaper materials. At the end of his talk, he outlined for challenges for robotics:

- Visual object recognition on a par with a 2 year old

- The language capabilities (not vocabulary) of a 4 year old – noisy environments, grammer

- Dexterity of a 6 year old

- The social understanding (model of the world) of an 8 year old.

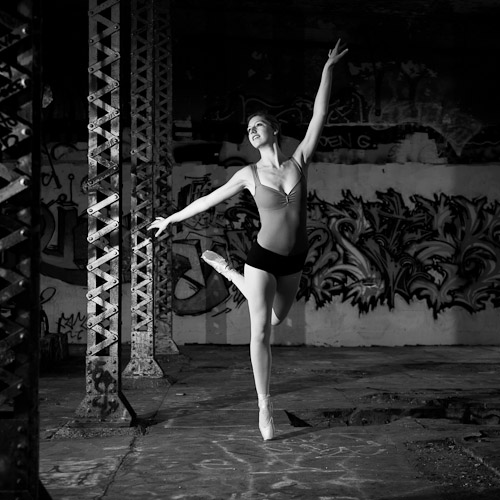

The other talk was Carin Meier’s robotic dance party. This one was purely selfish. My 13 year old is interested in space/robotics, so when Carin did a version of this keynote at OSCON, I showed my daughter the video. She ended up doing a school project on drones. As part of the way her school does projects, she needed to get an “expert”, so I gave her Carin’s email. That eventually resulted in some tweets. For Solid, Carin expanded the scope of the dancing and added some nice music control via Clojure’s overtone library. It was fun to find her afterwards and thank her in person for helping / inspiring my daughter.

Final Thoughts

The most motivational thing about Solid was a mix of ideas from Astro Teller’s talk about GoogleX, and a quote from Jeff Hammerbacher. Teller said (my paraphrase) “most of the world’s real problems are physical in nature, you can’t just solve them with software”. Hammerbacher is responsible for a quote that went around the internet back in 2011 that goes something like: “The best minds of my generation are thinking about how to make people click ads”. A lot of bright people have gone into software because the malleability of software and the internet means that you can make something and see the impact of it in a very short time. I’m excited to see progress in making hardware development more accessible and rapid. Perhaps that will lead to more bright minds finding ways to solve important physical world problems.